Ponti-yakin.

Ponti-yakin is talking about Pontiacs --

discussing, cussing, learning, teaching, and having fun with them.

Since I've had my 56 Safari, September 2001, I've

been learning about theses cars, mostly from Bob Johnson, a 56 "expert" who's

had six 1956 Pontiacs since 1968, including a couple of Safaris and currently a

convertible with restoration in progress (see

About Bob). He used the subject "Ponti-yakin"

in some of our emails; I like that terminology. Here is some 1955, 1956,

1957 random Ponti-yakin I think is worth keeping, perhaps some of it will

evolve into full articles (like the initial wire wheels Ponti-yaking turned into the

Wire Wheel Covers

article). Perhaps I'll organize it somehow someday but for now, I'm just

publishing as random questions/answers for your entertainment and education.

I'll probably add to to the top of the list as good informative Ponti-yakin

happens.. Larry Gorden

1956 Full Disk Hubcaps (Star Chief and 870)

Question. Most 1956 Star Chiefs

and 870s came standard with full disk hubcaps. What are the two

different types?

Answer from Bob.

Basically, the type I call "Tiger Teeth" or "saw tooth" uses a series of

serrated flanges (sort of like a saw toothed edge) rimming the reverse side

of the full cover cap. These are a press fit into the steel rim to grip the

wheel, and consequently are often dented from rough handling during tire

changes. The "Dimple/Pimple" or "Wheel Bump" type have a continuous stainless

steel rolled rim on the reverse side of the cover with several depressions in

this rim that snap over a series of small bumps (maybe "pimple" would be a

better description) on the original style steel wheels for '56 Pontiac. I

believe there are about half a dozen of these bumps on the steel wheel. These

"wheel bump" type are easier to get on and off, so are usually don't show as

much rough handling damage.

The two types (upper is '56, lower tooth type is '55)

The first type tend to

make a clicking noise (most often on the front wheels) when the car is

rolling at low speeds (suspect this is due to flexing of the steel rim given

the engine weight up front), but the second type don't stay on the cars very

well, particularly in hard turns or going over speed bumps, so it's debatable

as to which type is better.

The "dimple/pimple" type

have the added disadvantage of requiring the correct Pontiac rims with the

corresponding "pimples" on them, or the covers simply will not mount to the

rim.

1955, 1956 Rear Bumpers..

Question. Are all the rear

bumpers the same, excluding the 860/870 station wagons?

Answer from Bob.

There is a difference between '55 and '56 Starchief/Chieftain rear bumper

blades. Since in '55, they did not offer dual exhaust, bumper blades with the

two holes in the bottom to accept exhaust tips are a '56 only item.

The real beauty about

these bumpers though, is that with a good template, a few drills, a welder,

and access to a plating shop, you can modify any '55 or '56 rear bumper blade

fit any other design by drilling & filling holes as necessary.

As best I can recall, yes all '56's did have the two holes whether equipped with

the exhaust tips or not. All the Chieftains I've ever owned or saw had these

holes despite most of them not even having dual exhaust, let along exhaust

tips.

From what I've learned

over the years, the 'assembly plant' mentality is to make all parts as totally

interchangeable as possible. They certainly didn't want to either stop the

line (worst case) or have to add more space on the line (second worst case)

for different bumper wings just for the occasional car coming down the line

with exhaust tips specified on its build sheet. Labor and time "on the line"

were the major cost factors (and probably remain so today) in running the

assembly plant. Materials, when dealing in the volume that car manufacturers

do, were the cheap part!

This idea of total

interchangeability even applied to replacement parts as the cars aged. If you

research this in the master parts catalog, you'll often find four to six years

after a car may have first been built, that various replacement part numbers

in the most current master parts book often change from the original. I

believe this is the result of re-engineering (or 'reverse engineering') of

parts to fit multiple years. The later numbered parts often have slight

differences in appearance to the original assembly line pieces, but generally

are the functional equivalent of the original. This goes on even today in the

industry.

1955, 1956 V8 Emblem.

Question. What

types of V8 emblems were found on 1955 and 1956 Pontiacs?

Answer from Bob.

There were several versions of the "gold" V-8 emblem used on 1955 - 56

Pontiacs. Currently Ames Performance has available reproduction emblems that

are generally recognized as "correct" for 1955 Pontiacs and similar to 1956

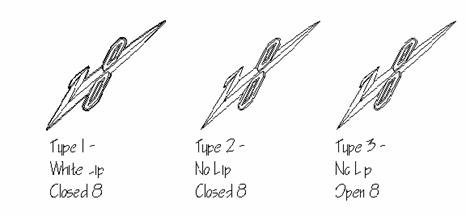

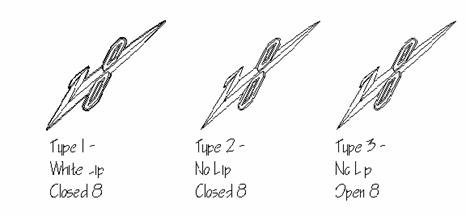

Pontiacs. The drawing below shows the three types with which I am

familiar.

Type 1 - is a

heavy-weight base metal (presumably pot metal) emblem plated with a shiny

polished gold plating (probably brass, since the color is very "brassy") that

also has a narrow lip around the perimeter of the emblem. This lip is painted

white. I believe the "holes" in the 8 are "closed" with a pebble finish

background, but since I don't have any of these emblems in the parts bins

(considering them to be '55 only) I'm unable to confirm this. Some folks

claim these emblems were used on early production 1956 units as well as 1955.

Type 2 - is a

light-weight aluminum base metal emblem anodized with a matte-finish bright

gold (yellowish like 14 K gold) anodized plating and the "holes" in the 8 are

"closed" with a pebble finish background.

This is the emblem type I

believe is generally correct for most 1956 Pontiacs. More often than not, used

emblems of this type have the gold anodizing rubbed off, since the finish is

very thin. The finish matches the finish used on the "Pontiac" crest used on

the speaker grille. This type V-8 emblem is the one I have personally found

as original equipment on every 1956 Pontiac I've either owned or found in the

wrecking yard and at most meets in Southern California. However, at the meet

in Niagara Falls back in 1983, I found the polished gold "Type 3" emblems on

some '56's at that show. Hence the dilemma.

Type 3 - is an

emblem type I've found in a heavy base metal plated with a shiny polished

gold plating (again, the color appears brassy), but this emblem has "open"

holes in the 8 so that the painted finish of the car is visible through the

holes.

I've been told these were

used in early production 1956 vehicles, but that's only hearsay. I've never

been able to document which years may have come with open 8's and/or whether

they were early or late production changes, or for that matter, a difference

dependent upon the plant in which the car was assembled. If the Type 1

emblems used on

1955 are also "open" 8

types, it's possible this was a transitional emblem used in early production

1956's before the Type 2 emblems were available, and reused the old '55 molds

simply omitting the painted lip.

That might explain why

some believe Type 1 emblems were used on 1956.

If the finish were the

same polished brass finish some folks would never notice the omission of the

lip. Of course, this is all conjecture on my part at this point.

1956 Horn Button.

Question. What

do you know about the 1956 Horn Button on the Deluxe steering wheel?

Answer from Bob:

There were two types of horn buttons. One type uses a stamped steel outer

shell that is crimped over the backing plate to hold it all together. This

type is nearly impossible to get open and I've not found a way to neatly close

it back once you do open it. The other type, though, used a pot metal outer

shell that has three peened pins to hold it closed. The pot metal unit has

very crisp square edged ridges, and is a much nicer looking button. These

units can be opened and closed again if done carefully and gently, so you can

replace a cracked lense, or for that matter switch from a standard to power

steering lense and backdrop. Standard steering units typically have a silver

tapered cone and silver back drop behind the Indian Head. Power steering

units typically have a gold tapered cone and gold back drop behind the Indian

Head. So there's more difference to these buttons than just the lettering on

the lenses.

1955, 1956 Radios.

Question. My 1956 radio doesn't

work, what should I look for?

Answer from Bob.

These old radios are built in two parts, the receiver, which has the knobs,

tuner and push buttons, and the amplifier where most of the tubes, the

vibrator, and the speaker are mounted. The two simply plug together and the

amplifier is the same for all three radio types used (standard, deluxe and

wonderbar). If I recall correctly, there is a three prong plug with

steel-braid shielded wires that connects the two together, and the amplifier

is held up in the dash by two large pan-head phillips screws that screw up

through the bottom edge of the dashboard.

There should also be a

brace between the amplifier and the receiver that will need to be

disconnected. Then the whole amplifier unit comes right out from under the

dash complete with the speaker.

The power lead runs

between the radio receiver and the fuse block, and the antenna lead plugs into

the receiver as well, so unless the wires interfere with removal of the

amplifier, you needn't disconnect them.

As for the radio, you

might also try hooking up an external antenna (a little $5 replacement antenna

from Pep Boys or Kragen makes for a good bench tool, although in a pinch, even

a coat hanger hooked to the old antenna stub can sometimes work)....the point

is to ensure you have a good antenna feed into the radio. With the antenna

attached and fully extended, put the volume up moderately high (or as loud as

you and your neighbors can stand it), and then twist the tuner knob to see

what you get. Usually the push buttons are set to a "local" station, but who

knows where "local" was when the car was last used.

Even a crackly signal

with somewhat inaudible or garbled words will mean the radio's

working....though the next diagnosis problem may be to determine whether you

need a replacement speaker (chances are good you will). The cones in these

tend to dry out and tear....making them crackle and rattle instead of giving

good clean sound. but a pair of jumper wires from each of the two speaker

leads to a good speaker will quickly determine if a replacement speaker is

needed and whether the speaker circuit is functioning properly.

All years, Oil Pressure Line Restoration.

Question. How did you restore your oil pressure line?

Answer from Bob. I've also now finally got a good oil pressure line

in place from the filter to the dash gauge. I believe I told you, I had a

really nice line all cleaned up, refinished and 3/4 installed, when I flexed

it a bit too much and the line kinked and broke. That cost me about 8 hours

worth of work right down the drain.

I've learned another

couple of lessons in the process. First, when reinstalling this line it's

probably wise if you don't fasten it down to the firewall or install the

firewall rubber grommet until you have both ends of the line screwed into

place. This leaves more flexibility in the line so you can get it properly

positioned to screw in the ends without it kinking. I had everything fastened

down tight while trying to fit the filter end of the line into its fitting,

which is likely why it kinked.

Second, as you know,

these steel oil lines have an asphalt treated cloth covering on the line from

about an inch from the gauge to just about an inch or two below the point the

line makes a 90 degree vertical turn at the ignition resistor and heads down

to the oil filter. This cover provides a heat insulator to protect any wire or

plastic that may otherwise come in contact with this "hot" oil line under the

dash, as well as to protect the mechanic's hands from burns when working on

the ignition system. Generally speaking, the portion of this cloth cover

that's exposed under the hood is rotted, dry and crumbly, if not already gone,

due to the abuse and weathering to which it's been subjected over the years.

To "restore" this line

and its covering, I first gently washed the line in simple green, and then use

a wire brush wheel to as gently as possible remove all old dirt, rust and

grime from the line itself. This was followed by a good metal polish to

brighten the line. It has a very light clear zinc original finish that will

probably either already be worn off, or may polish off in the clean-up

process. Thus, for rust resistance it's probably advisable to coat the line

with a good grade of heat resistant clear finish after it's repolished.

To "restore" the asphalt

impregnated cloth cover, I've neatly cut off the rotten part of the cover

squaring up the end, then gingerly slid the cover along the oil line,

carefully working around the bends and turns, so the sound portion of the

cover that was previously under the dash will now be exposed under the hood.

This of course leaves the portion of the line under the dash bare. To "fix"

this problem, I used a larger diameter piece of similar cover material (large

enough to fit over the line fitting) and slipped it over the interior end of

the line, covering all but about the last inch of the line at the gauge end

and lapping the larger cover over the end of the original cover under the

dash. This may be best done before you put the line into the dash. Thinking

it would be easier to install the bare line through the firewall, I did it

afterward and had a bit of a struggle working the cover around the bends in

the line, particularly in the confined space under the dash.

This larger diameter

cover material is commonly used for headlight wire harness work, and so I've

found it available through some of the wire harness vendors at Pomona. I'm

not sure just how hot the line gets, but suspect it's probably hot enough to

melt plastic insulation.

Anyway, then I soaked the

portion of the original cover that will be exposed under the hood in

Eastwood's "Underhood" semi-gloss black paint (i.e. I sprayed it heavily and

let it soak in). The end product looks absolutely original. The paint seems

to toughen up the cover and I believe will make it easier to keep clean since

the original asphaltic coating tends to attract and hold dust and dirt. I

suspect no one will know the difference unless and until they crawl around

under my dash!

1956 Remote Control Mirror.

Question. I saw a remote control mirror on ebay, what to you

think about them?

Answer from Bob.

I believe a rough remote control mirror may be more trouble than it's worth.

These things are extremely rare and so replacement parts are really tough to

come by. If you find an NOS or mint unit complete with installation

details/instruction, it would be a great option to have, but I'd hate to have

to try and restore one that's pitted/dented and needing refinishing, or worse

still, broken or inoperative, and then there's the challenge of trying to

figure out how it installs properly. If you didn't take it off of the car it

was on, and get patterns for the mounting holes etc., it can be a real

challenge! Many of these things are counter-intuitive. It's always best to

talk to the man who has one....so if you buy, you'll need to find a club

member who has one installed on his car to get good advice!

Charles Sihilling, the

plater I use, tells me the only way to refinish these old mirrors is to break

out the glass, remove the stainless "reflector dish" piece, replate the base,

then reinstall the stainless piece (after polishing it), and then replace the

mirror glass. Because the mirror glass is a press/formed-fit in the stainless

dish, I've never found anyone who claims to be able to do this, and I've never

attempted it on my own. I'm not sure it can be done without damaging the

stainless.

All years, Used Plastic Parts.

Question. Where is the best place to get used plastic parts such

as dash knobs?

Answer from Bob. When looking for replacement plastic and interior

parts, units from the Pacific Northwest and back east will generally be in the

best condition; look for rust free metal and exterior trim in the southwest,

but expect any fabric/plastic and painted finishes to be shot from all the

heat and low humidity!

Safari B-Pillar Paint Scheme.

Question. What

do you know about the post color on the Safaris? All the sales stuff show the

post painted the same color as the bottom. I've seen pics of a couple painted

like that but most have the post painted the same color as the top. Perhaps

they were painted different in different plants or perhaps they changed it mid

year.

Answer

from Bob. You

are correct that the official literature issued by Pontiac shows the color

split at the top of the B pillar with the pillar painted in the lower body

color. But, I (and most other Safari enthusiasts) don't believe any cars were

every actually painted that way from the factory. Despite the literature,

I've never seen any period pictures or dealer photo's that show the color

split at the top (thank goodness...to me, it looks awful that way).

If you look again at the

web site you directed me to, you'll note that the two tan and white cars that

had pictures available are both painted with the 'B' pillar in the upper body

color, but they also both are painted with the most common "error" in terms of

the color split line. Both of the Safaris pictured at the web site have the

paint split "dipping down" into the body line, which is technically

incorrect.

The "factory" color split

is a straight line originating at the point on the rear edge of the door

opening in the crease between the pillar and the body bulge. From there, it

extends in a straight line until meeting the lower reveal molding on the

sliding side glass window. The upper body color, as painted from the factory,

did not extend down into the "dip" in the body bulge, although admittedly, to

do so does accent one of the most pleasing lines on the car.

My Safari was painted

with the straight line (not dipped) separation which matched the original

factory paint layout on the car before the re-paint. So to me, whether any

cars were ever factory painted in a different manner didn't really matter. I

knew this car at least was repainted to match the original factory finish.

The straight color split

line was apparently used to match the look of the Nomads, even though the

Nomad bodies do not have the same "voluptuous" body curve like the Safari.

Many people have never noticed that subtle difference between the two makes.

The absence of the "dip" on Nomad's has always seemed strange to me, since the

Chevy hardtops/convertibles, like the Pontiac, do have this same body contour

line. I guess the Nomad stylists at Chevrolet just didn't recognize a good

thing when they saw it. But then, some would say that neither did Pontiac

since they didn't accent this body line by "dipping" the color separation

line.

Oh well! ....and so the

controversy continues...to dip or not to dip! At the end of the day, if

you're a "purist" you don't dip....if you're more relaxed about absolute

authenticity, perhaps you do!...it's really a personal choice, The

non-enthusiast will never know the difference, and few Safari "experts" will

ever fault you either way.

Safari Carpet.

Question:

I have original carpet in

the loading area of my 56 Safari+ but not on floors. The loading area carpet

is a short loop carpet and I guess that must be "Daytona Weave". Is that

correct?

Answer from Bob.

Yes, the floor carpet and

cargo area carpet are the same weave....but the backing on the originals is

slightly different. The cargo area used a thinner backing (go figure) than

the floor carpeting. Also, in the Safari's there is an area of the floor

where a colored rubber mat was used rather than carpet. Specifically, under

the folding rear seat. This area is generally only seen when one is operating

the folding the seat, but if your looking for absolute originality, it's one

more detail to fuss over. I've yet to see one still intact in any Safari out

here on the west coast....but back east a lot of rubber, cardboard and plastic

items held up a lot better due to the more humid weather. Out here things

seem to dry up to crispy critters rather quickly. Of course we have a lot

less rust and our exterior bright work holds up better....guess you can't have

everything.

Question: What carpet was used in 1957?

Answer from Todd Crews. POCI 1957 Technical Advisor.

Daytona Weave

was used in 1955-56, but changed in 1957 to the regular 80/20 loop.

Safari Exhaust pipe deflector

Question. Did

the Safaris have a tail pipe deflector?

Answer from Bob.

Safari's used a unique exhaust deflector accessory different than the exhaust

tips for other Star Chief models. The exhaust deflector used is the same as

was available for 1955 (which were all single exhaust cars), and is a chrome

plated "tin" exhaust tip that clamps onto the end of the tail pipe. It's a

very unusual design and a highly sought after option.

1955, 1956 Safari "Knuckle Buster".

Question. What is a "Knuckle Buster"?

Answer from Bob. "Knuckle buster" is the nickname given an early

production center rib that was used on some '55 Safari's and Nomads.

Essentially, the difference between the knuckle buster and the late production

center ribs was the "section view" of the rib through that portion of the rib

that was between the two mounting holes for the tailgate handle.

On the "knuckle buster"

this section carried through the handle with the same ribbed section. On the

late production ribs, the section under the handled was modified (flattened)

to allow more room for your hand to lower and raise the gate without banging

your knuckles on the rib contour.

My

Safari #2 had an "NOS" Knucklebuster center rib on the tailgate. Urban legend

has it, some parts dealer/supplier found a stash of NOS knucklebusters left

over from the change-out in production.

Others simply claim the knucklebuster was the first center rib to be

reproduced because it was so rare....but these are just "legends"...I've never

been able to substantiate either story. Not too many folks even want the

knucklebuster these days, but it's an interesting bit of trivia.

Ponti-Yakin

Question: Do you have any good Ponti-yakin?