Early Pontiac V-8 Engine Cooling

By Larry Gorden

December 2007

Beginning

with the first production engines in 1955, Pontiac V-8

engines were cooled by reverse flow meaning the cooling water enters and

cools the heads first and then some of the water enters the block and cools the

cylinders.

In 1960,

Pontiac abandoned the reverse flow system in favor of “conventional” flow where cooling

water enters the block first and cools the cylinders -- then all the water flows

into the heads, cools the valves, and returns via the intake manifold to the

radiator.

The

difference in reverse flow and conventional flow is in how water circulated

through the engine, not how it circulates through the radiator.

In both cases, cooling water is taken from lower radiator and hot water

is returned to the top of the radiator.

Each

system of cooling is explained below.

1955-59 Cooling (Reverse Flow)

The following is found in the Shop Manual for each year from 1955 through 1959.

My comments are added in double brackets like [[my comment]].

I added the photos and highlighting also.

COOLING SYSTEM CIRCULATION

Pontiac cooling system uses reverse flow

circulation for maximum cooling efficiency. In reverse flow, cooled water

from the radiator passes first to the cylinder heads, which are the hottest

parts of the engine, and then to the cylinder block which is the coolest

portion of the engine.

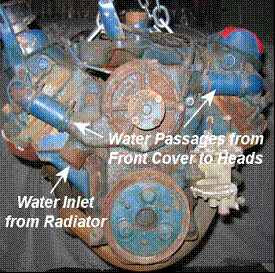

Water enters each cylinder head from the pump through a

water distributing tube [[that is inserted into each cylinder head]].

[[Water Distributing Tube]]

Openings in the water distributing tube direct coolant

in jet fashion onto valve seats and around each exhaust passage. This

feature is referred to as “gusher

valve cooling”.

The combination of reverse flow circulation and gusher

valve cooling results in relatively low operating temperature of valves and

valve seats. Valve life is greatly increased, therefore, and valve seat

inserts are not required.

With reverse flow circulation no cooled water is thrown

directly on cylinder walls to cause cylinder distortion. Sludging of engine

oil is minimized since highest temperature coolants are retained in the

cylinder block, particularly during warm-up, and condensation on cylinder

bores is thereby reduced.

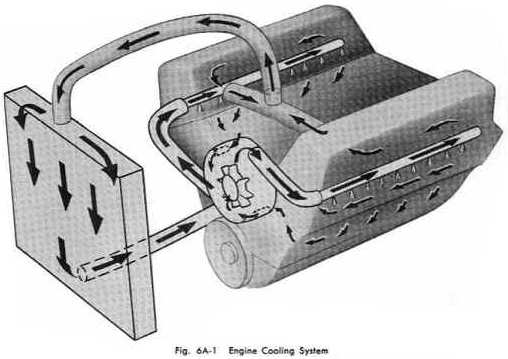

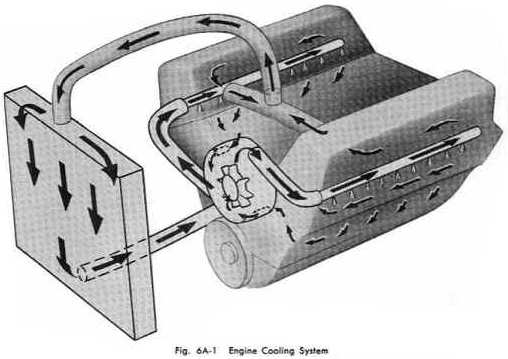

Water circulation during warm-up (thermostat closed) is

from the pump to the water distributing tubes to the cylinder heads,

[[1956 engine]]

down into the block and back to the pump through

passages from the front of each bank to the water pump inlet (Fig. 6A-1).

[[Source 1955 through 1959 Pontiac Shop Manuals]]

Water circulation after normal operating temperatures

are reached (thermostat open) takes two courses.

Part of the water

will always recirculate through the block as outlined above. A large portion

of the water, however, will pass from the pump to the water distributing

tubes, to the heads, and thence directly into the top of the radiator

through the water outlet page in the front of the intake manifold.

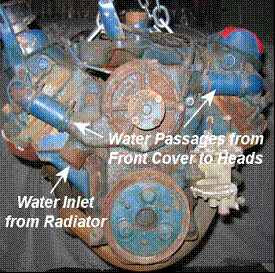

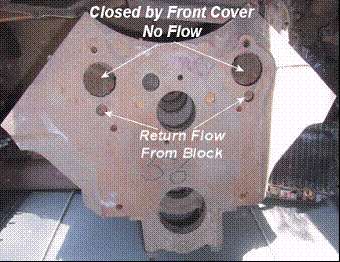

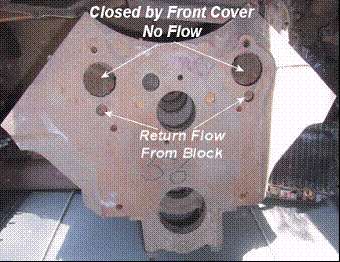

1956 Front cover and front of engine block

1960 Cooling (Conventional Flow)

The following is found in the 1960 Shop Manual.

I added the photos and highlighting.

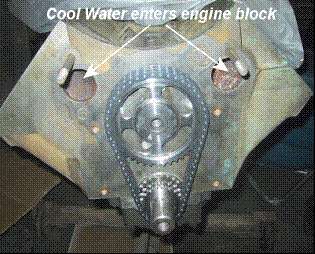

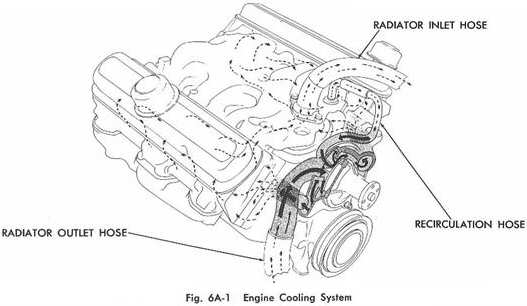

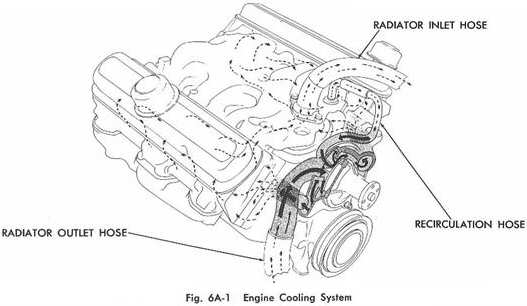

The inlet side of the water pump is

connected to the lower radiator tank by means of a hose. A small

recirculation hose connects the water leg of the intake manifold to the

timing chain cover (which acts as the pump body) to provide recirculation of

water when the thermostat is closed (See Fig. 6A-1).

COOLING SYSTEM CIRCULATION

Water circulation is provided by a single impeller,

specially designed water pump which provides a balanced flow of water into

each bank of the cylinder block.

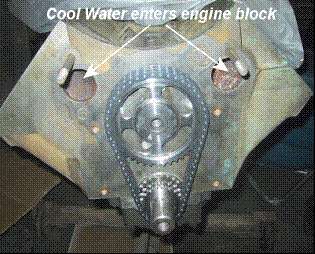

[[1960 front cover and front of engine block]]

Water circulation during warm-up (thermostat closed) is

from the pump to each bank of the cylinder block, up into the cylinder

heads, into the front of the intake manifold, and back to the inlet of the

pump via an external recirculation hose connecting the intake manifold and

timing chain cover which acts as pump body (Fig. 6A- 1).

Source 1960 Pontiac Shop Manual

1960 Engine (1957 intake manifold &

Generator)

Water circulation after normal operating temperatures

are reached (thermostat open) takes two courses. Part of the water will

always recirculate as outlined above. A major portion of the water, however,

will circulate into the intake manifold as outlined above, but will then

pass directly into the radiator via the outlet passage and hose above the

thermostat and thence back to the pump inlet.

The water pump and the

water transfer holes

between the block and cylinder heads have been designed to provide an

equitable flow of coolant, and provide temperature balance in both

banks of the engine and within each bank and its cylinder head.

Engine Differences in Reverse Flow and Conventional Flow.

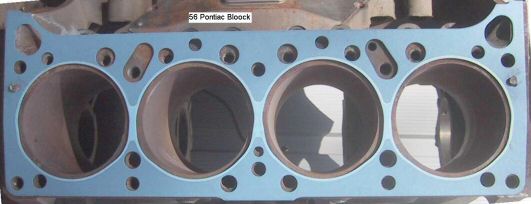

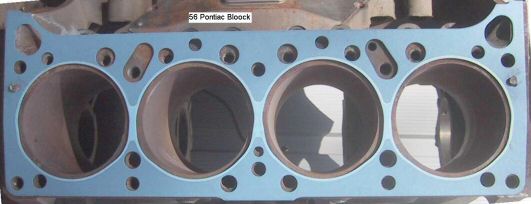

I’ve compared closely a

1956 block with a 1960 block (reverse flow with conventional flow) and 1957

heads with 1960 heads.

I would expect the same differences between a 1959 and 1960 block/heads.

Differences I see are:

-

Reverse

flow heads must have the water distributing tube installed in each head.

The 1960 heads do not use them. 1960 heads can be used on earlier

years by installing the tubes. Earlier year heads can be used on a

1960 engine by removing the water distributing tubes and installing a freeze

plug in the head inlet water passage. I compared 1957

heads with 1960 heads and there is not apparent difference.

-

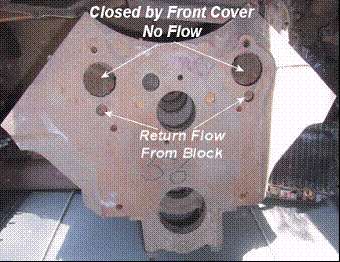

The front covers (timing chain cover and water pump housing) are completely

different but either front cover will bolt up to either block (same bolt

pattern and same front seal) -- but due to water flow differences, they must

not be interchanged.

Front Covers (1960 left in each photo, 1957 right in each photo)

Note on the backside of the

1957 front cover (on the right) that the large holes are closed although they

may appear to be open water ports.

Front of Block, 1956 (left) and

1960

The upper front first three water ports that you find on the reverse flow block

are missing on the 1960 block on each side. Ports towards front and on

bottom of deck are smaller on the 1960 block than the reverse flow blocks. This obviously is to force

more water to the back of the engine and to lower side of heads to provide

controlled cooling for the 1960 engine. The 1960

Shop Manual says "water transfer holes

between the block and cylinder heads have been designed to provide an

equitable flow of coolant" which

likely refers to this change in water ports.

1960 Deck (click for enlarged view)

1956 Deck with 1960 head gasket (click for enlarged view)

Why Did Pontiac

Abandon Reverse Flow?

The 1959 Shop Manual talks about why reverse flow cooling was used and extols

the benefits of reverse flow and gusher valve cooling. Why did Pontiac abandon the documented superior

cooling system and switch to

conventional flow in the 1960 model year without any explanation?

No one seems to know for sure but here are some theories:

Theory 1:

“PMD

APPARENTLY MOVED AWAY FROM GUSHER FLOW, PRIMARILY BECAUSE THE ENGINES RAN TOO

COOL IN COLDER CLIMATES”

Source: Rick Gonser POCI Chief Judge, Western District Director, and 50s/60s Pontiac Guru

That theory doesn’t (dare I

say?) “hold water”. If a

hotter engine is needed, why not just replace the thermostat?

To change the basic flow design in order to make the engine warmer just

doesn’t make sense.

Theory 2:

“All Pontiac V8s from 1955 to 1959 were reverse

cooled, known as the "gusher" cooling system. It was plagued with corrosion

issues and was removed from the design for the 1960 model year due to warranty

returns.” Source

http://en.wikipedia.org/wiki/Pontiac_V8_engine

A lot of the reverse flow

engines are still running around.

I haven't heard of any issue with corrosion in the engine.

So that theory doesn’t make sense.

Theory 3: Pontiac

made the change

to free up the fronts

of the cylinder heads for accessory mounting

Sources: Pontiac Jack and Charles Coker

This could have been done to allow mounting more accessories outboard of the engine

and thus allow for lower front hoods.

I'm not sure I buy it. The elbow and short water hose on the front of the

engine didn't take up much space. Plus the hood was lowered considerably

in 1959 when they still used reverse flow cooling.

Theory 4:

Pontiac

abandoned reverse flow in 1960 to improve cooling around the cylinders

Source: pulled

from thin air.

This theory is based on what the switch really did differently in cooling the engine.

The 1960 engine will provide much better cooling around the cylinders

than the old reverse flow system.

All the incoming cooling water will flow around the cylinders before

exiting the block and going into the head to cool the valves and combustion

chambers. Water cools the cylinders first

where it warms up a bit, and then the water

cools the upper end (heads).

Is

this Theory 4 correct?

Maybe not -- I've not heard it from anyone. It would make sense only if

Pontiac

was seeing problems with cylinders overheating in reverse flow engines when stressed.

As displacement got larger, compression went higher, and engine heat

increased to get better performance, it may be that the cylinders were getting

inadequate cooling – which would likely not show up on the temp’ gauge but would show

up as piston failure in “stressed” engines.

Reduction in manufacturing cost has been offered as another possible reason for

the switch.

So far, I've been unable to find anyone that can verify the real reason for the

change.